There is no circulation in the radiator. What should a homeowner do so that problems with the heating system are not taken by surprise. Circulation pump not working

Electric heating and stove supply. Steel pipe 32 at the outlet diverges in two directions. The right wing of the house heats well, in the other it is cold, the system is single-pipe by gravity, the expansion tank is homemade.

I tried to put a regulating valve, but it’s no use anyway, the cold side does not heat well, although the boiler is boiling with might and main. It is advised to install a pump, but when the electricity is turned off, the whole system turns out to be up. How to be

?

The specialist of the company "RST" answers:

A very common question. The lack of heat in one of the circuits is simply explained - there is no circulation or it is difficult. Why? There are many reasons.

Water moves along the path of least hydraulic resistance. And if it’s quite simple, then where it’s easier for her to “run”, they will “run” there. And if the coolant flows freely into one wing, and not into the other, then there is no circulation. The reason for the lack of circulation may be narrowing the diameter of the pipe (switching to a smaller diameter), poor-quality installation of the pipeline, faulty shut-off valves (taps), airing the heating system (lack of automatic air vents at the highest point of the pipeline), just elementary construction debris or dirt.

Now, as for the circulation pump. Be sure to set. And don't worry about power outages. The efficiency of the system will increase. And you will feel it right away. And so that the circulation in the heating system does not stop, in the absence of electricity, the circulation pump must be installed on the bypass circuit (bypass). Then the coolant, bypassing the bypass and the pump, will go through the main pipe of the gravitational heating system.

>> There is no coolant circulation in the heating system - what are the reasons?

No circulation in the heating system - what are the reasons?

If there is no coolant circulation in the heating system, then there is nothing to talk about any comfortable living in the house in winter. Because no matter how hot the boiler is, the radiators will still be cold. However, you need to think about this not when the system “worked, worked and suddenly stopped”, but even at the design stage, i.e. now. In this article, we will deal with the problems leading to poor circulation of the coolant.

Causes of poor coolant circulation

There may be no circulation of the coolant in the heating system for the following reasons:

- insufficient power of the circulation pump (or pumps, if there are more than one). For this reason, the coolant simply does not reach the radiators farthest from the boiler, so they are cold (or slightly warm, which is why it’s not easier anyway). On how to choose the power of the circulation pump, there are several articles and videos in the heating design section;

- non-return valves are not installed. Usually their absence is "painful" for complex systems with several circuits. Check valves are used to ensure that the coolant moves along the desired circuit and in the desired direction (read more below);

- system contamination. It happens that the pipes are clogged along the entire diameter - what kind of circulation is there! It is treated only in one way: by replacing the pipes. This is exactly the case when the best treatment is prevention. And "prevention" should be carried out at the stage of installation of the pipeline and radiators. First, make sure that debris does not get inside the pipes. To do this, first making sure that there is nothing inside, we close the ends of the pipes with something before installation. For example, it is convenient with simple plastic bags. Secondly, there may be debris in the radiators. Even new ones! So we check and get rid of;

- pipe diameter is too small. Small pipe diameter - high hydraulic resistance - the pump is not able to “push” the coolant through the entire pipeline - there is no circulation in the heating system (well, or it is so bad that it doesn’t matter that it doesn’t exist). Again, at the design stage, you need to calculate the hydraulic resistance;

- accumulation of air in the system (airing). Air, of course, is not garbage, but air congestion in the same way will not allow the coolant to circulate freely. Air congestion may appear due to violations of the heating system installation rules. Getting rid of air is easy - install an automatic air vent at the highest point of the system and Mayevsky taps on radiators.

Coolant circulation in a combined (branched) heating system

Let's start the analysis of the circulation of the coolant with a complex system - then you will deal with simple circuits without problems.

Here is a diagram of such a heating system:

It has three circuits:

1) boiler - radiators - boiler;

2) boiler - collector - water heated floor - boiler;

3) boiler - indirect heating boiler - boiler.

Firstly, the presence of circulation pumps (H) for each circuit is mandatory. But this is not enough.

In order for the system to work as we want it: the boiler is separate, the radiators are separate, check valves (K) are needed:

Without non-return valves, let's say we turned on the boiler, however, the radiators "for no reason" began to warm up (and it's summer in the yard, we just needed hot water in the plumbing). Cause? The coolant went not only to the boiler circuit, which we now need, but also to the radiator circuits. And all because we saved on check valves that would not let the coolant through where it is not needed, but would allow each circuit to work independently of the others.

Even if we have a system without boilers and not combined (radiators + water heated floor), but “only” branched with several pumps, then we put check valves on each branch, the price of which is definitely less than altering the system.

Coarse filter

As mentioned above, one of the reasons that there is no circulation of the coolant may be the accumulation of debris in the pipeline. In order to completely avoid this, again, we do not save on pennies, but put a coarse filter in front of each device:

With the help of a filter, it is easier to catch dirt than to correct the consequences of clogging of the pipeline or boiler heat exchangers.

Conclusion! We put coarse filters in front of each device of the heating system (pump, boiler, etc.) and in front of each plumbing device. We DO NOT save pennies to "buy" problems. Arrows are embossed on the filter housing indicating the direction of movement of the coolant or water in the water supply ...

The filter needs to be cleaned regularly. And it is very simple to do this: close the valves before and after the filter - unscrew the plug (1) on the filter - remove and rinse the mesh under the tap - insert it into place and tighten the plug. Everything. Not like changing pipes :)

In order for the house to always be cozy and comfortable, you must first take care of the heating system. Indeed, in the cold season, the optimal room temperature not only creates normal living conditions, but also has a positive effect on human health. Currently, there are various ways to heat a house, but water heating has long been considered the most effective option to this day. Especially the heating system. With its help, you can create comfortable conditions in any house, regardless of its size and number of storeys.

The principle of operation of the heating system with forced circulation

To properly understand how this scheme works, you must first understand the system with natural circulation. coolant is quite simple.

The coolant in the heating boiler picks up the required temperature and, according to the laws of physics, rises up the riser. Having reached the radiators, it leaves part of the thermal energy, so here the water temperature decreases.

Under the action of the newly incoming hot water, the chilled water gradually descends into the boiler, where it is heated again. And the whole cycle repeats again.

What are the disadvantages of this scheme, and why is it not so in demand? This scheme does not work well when the heating system has a single-pipe piping pattern. This is especially true for multi-storey buildings. In this case, there is an uneven distribution of heat over the radiators. The batteries closest to the boiler heat up more, and the distant ones less. In some rooms the temperature is higher, in others it is lower. And to prevent this from happening, it is necessary to build up sections on the radiators in the back rooms.

In addition, the amount of fuel consumed by the boiler in a natural circulation system is always greater than when a circulation pump is installed. And this is an important factor today.

If a two-pipe system is used, then these problems disappear by themselves.

Now it is clear that the low efficiency of such a system requires the installation of a pump in it. It increases the speed of movement of the coolant, and this, in turn, ensures a uniform distribution of hot water across all heating devices.

This system is safe.

Many may doubt the correct operation of such a system - after all, there is a possibility of mixing cold and hot water. That's right, such a possibility would exist if the coolant velocity were too high. But modern circulation pumps create a slight pressure, at which the speed of the water inside the heating system is practically no different from the natural one. There is a slight increase, but this in no way affects the mixing of water with different temperatures.

A very important point! The coolant under the action of the pump always moves in one direction, in which heat loss is minimal. And if you correctly regulate the speed of movement of the coolant, then you can control the amount of heat produced.

Advantages and disadvantages

So, the pump installed in the system provides it with a large number of advantages:

- For such a system, it makes no difference which pipes and with what diameter will be installed in it.

- In this case, inexpensive pipes with a smaller diameter can be used, which will save money.

- The absence of temperature difference increases the service life of the system components.

- It is possible to regulate the temperature in the system itself or in separate rooms of the house.

Of course, there are also disadvantages:

- Firstly, the pump is powered by an electric current network, and this, albeit small, but costs. In addition, in the event of a power outage, the pump also stops.

- Secondly, a small noise from the operation of the pumping unit. It is almost inaudible, but it is still present.

Heating schemes

Water heating

With forced circulation of the coolant, there are two types - one-pipe and two-pipe. The difference between them is quite significant. Here, not only the pipe layout differs, but also their number, as well as a set of shut-off, control and monitoring valves.

Single pipe heating system

Here, too, two options must be considered, because there is a horizontal and a vertical scheme.

The first option is very simple. All heating radiators are inserted into the network circuit in series. That is, the coolant from one device flows into another, followed by a return path to the boiler. Each device is equipped with Mayevsky taps, through which air is removed from the system, as well as taps or valves, with which you can cut off part of the system or one small section. The pump installed in such a scheme will be very relevant.

There is one point to which special attention must be paid. This scheme for a multi-storey building is used in variation, when each floor has its own separate branch from the riser.

The vertical layout is simplified. In it, the riser rises above the last floor, where the pipe is lowered to the upper floor and distributed along the radiators in a horizontal pattern from device to device. Further, the pipe descends to the floor below, where the horizontal wiring is repeated. And so on up to the first floor. Now you understand that the radiators of the first floor will always be cooled.

Two-pipe heating system

Drawing of a two-pipe heating system

In this scheme, there are also two types of wiring - horizontal and vertical. In turn, the horizontal scheme is divided into:

- dead end;

- Passing;

- Collector.

What are the differences between these three schemes?

The first is the simplest, but it is very difficult to control the temperature regime in it. Each radiator has its own circuit, and the farther the battery is from the boiler, the longer this circuit is.

In the second scheme, these circuits are the same, which makes it easy to control the process. But at the same time, the length of the pipeline itself increases.

But the third scheme is the most effective, because each radiator has its own separate pipeline, and the coolant is supplied through it. The uniformity of heat in this case is ensured. There is only one drawback - the large material costs for the purchase of a large amount of materials and considerable labor costs for installation work.

The vertical scheme is also divided into two types - with the lower wiring and with the upper one. The first option has a distinctive structural element - the coolant supply riser passes through all floors and enters the radiator at the top, from which there is a return. Through this pipe, water enters the lower floor, where it also enters the radiator immediately. And so on to the boiler. That is, in any room you will have two pipes.

More options for forced heating schemes

The second option is completely different. Here the riser rises vertically from the boiler to the attic, where pipes are routed to each radiator of the upper floor. And from them a pipe descends to the lower floor. This return line is suitable for the lower floor radiator as a coolant supply. That is, in each room you will always have one pipe connecting radiators on different floors.

As you can see, heating systems have different schemes. Choosing any of them, it is necessary to solve one very important question - how much money is allocated for the installation of heating in your home.

How to properly equip a forced circulation heating system

In order for the system to work for a long time, efficiently and without problems, it is necessary to correctly install some of its components:

- A mandatory heating element is an expansion tank, which is connected to the return circuit. It is necessary because vaporization processes are constantly taking place in the system, and it must be replenished with water. In addition, sometimes when the coolant is overheated, its volume increases. And the presence of a tank prevents its release.

- The circulation pump must be mounted in the return line. This is a simple necessity that helps to increase the life of the unit. The fact is that the design of the pump has rubber seals and cuffs. Under the influence of hot water, they change their properties. In the return, the water moves already cooled, so it does not affect the quality of the rubber elements.

- Forced heating system makes it possible to use pipes with a minimum diameter. This not only reduces the cost of building a heating system, but also saves on the coolant, expansion tank and the boiler itself.

- Install in such a system only modern heating boilers, with which you can control and regulate all processes. They are equipped with automation, and it will make it possible to use fuel efficiently, as well as to adjust the temperature inside the house, depending on various factors.

Choosing a circulation pump

![]()

Circulation pump

To choose the right pump, you need to take into account only two of its qualities. It should be:

- Energy saving.

- Simple and reliable in operation.

Indicators such as power and pressure are determined by the size of the house itself. For example:

- The area of the house is 250 square meters - choose a pump with a capacity of 3.5 cubic meters per hour and a pressure of 0.4 atmospheres.

- Area 250-350 cubic meters - power 4.5 cubic meters / h, pressure - 0.6 atm.

- Area 350-800 cubic meters - power 11 cubic meters / h, pressure - 0.8 atm.

Of course, it is difficult to say exactly which pump is best to use for a particular home. Here you have to make a calculation that only a specialist can perform. Indeed, for this it is necessary to take into account many factors.

This must include:

- The diameter of the pipes and the material from which they are made.

- The length of the entire system.

- The number of radiators, valves and other devices, as well as their type.

- The type of fuel on which the boiler will operate.

Glandless circulation pump for all water heating systems

As you can see, it is very difficult to take into account all the factors and make the calculation on your own, only a specialist can do it.

And the last. Often on the forums you can hear complaints from private developers that there is no circulation in the heating system. What to do?

There can be only one reason - these are air jams inside. To remove them, it is necessary to install Mayevsky taps on each radiator. This is an effective tool in combating the air that remains inside the system after it is filled with water. So you have to go broke and buy these devices.

By the way, at present such taps are produced with automatic air release. An excellent option in which there is no need to control the formation of air congestion.

In water heating systems, it is not uncommon for a problem to occur that leads to a deterioration in the circulation of water inside the circuit. The problem has a specific name - airing in the heating system. The uninterrupted operation of water heating is based on the principles of circulation of hot water (coolant) inside the circuit and heat transfer through radiators that heat the premises. The air in the system leads to the appearance of air pockets and, as a result, to the inefficient functioning of the entire system due to a decrease in heat transfer.

To begin to solve the problem, it is necessary to establish the causes of the appearance of air: natural or artificial. The natural cause is the airing of the system due to the property of heated water to release air. The higher the temperature of the coolant, the more air bubbles are released. According to physical laws, the accumulation of bubbles occurs in the upper part of the circuit, since air is lighter than water.

The rest of the reasons are considered artificial. It is difficult to give a complete list, but the main reasons are considered to be the following:

- lack of pressure in the system;

- errors in the installation of the heating circuit (for example, incorrect pipe slope);

- errors when starting the system into operation (for example, filling the circuit with water too quickly);

- high concentration of air in the water used;

- incorrect operation of the locking equipment (possibly loose connections of individual elements);

- blockage of pipelines;

- consequences of repair and maintenance work;

- corrosion on the metal surfaces of the contour elements;

- incorrect operation of air vents or their absence.

Consequences of airing

The disruption of heat transfer due to air locks is unpleasant for residents who pay for heating, but in fact receive an underestimated indoor temperature. But this is not the only negative, there are other negative consequences:

- noise and vibration during water circulation, which in the worst case is fraught with the destruction of integrity at the junction of the circuit elements;

- defrosting the system if there is no water circulation in several radiators;

- excessive fuel consumption in order to increase heat transfer;

- destruction of internal metal parts under the influence of air (due to corrosion).

The totality of all the consequences affects the operating capabilities and the overall service life of both individual elements and the entire heating system.

De-airing

Airing can occur when the system is filled with coolant and during operation. Situations are resolved in different ways, but it all comes down to air release using valves and taps built into the system.

Filling a closed system with forced circulation must occur in a certain sequence to avoid the formation of air pockets. Cold water is supplied from the bottom up, the air outlet valves are left open, only those installed for draining water are closed. Rising, the coolant squeezes out air through open valves and taps. As water begins to run through the tap, it is closed. So gradually, always smoothly, fill the system with water. The pump is started when the circuit is completely filled with coolant.

For air release, manual or automatic air vents, air separators are used. It is clear that the installation of manual air vents involves the release of air by the attendants or the tenant of the apartment (house). There are such air vents in ordinary residential buildings in the rooms of the upper floors or on technical floors. The Mayevsky faucet is known to many residents of old high-rise buildings, who independently discharge accumulated air every heating season. In new houses, it is practiced to install a manual drain valve on technical floors.

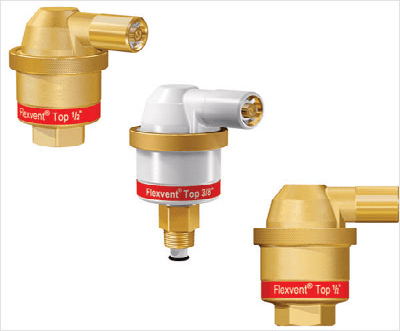

The automatic air venting system works separately from human participation. The principle of operation of automatic air vents is the same. In the body of the air vent there is a float on which water enters. The float presses on the spring-loaded rod, opening access to the outside. The body is gradually filled with coolant, the float presses on the rod and closes the outlet. In order for the air vent to work properly, periodically check the cleanliness of the needle and the suitability of the sealing ring for further operation.

It happens that the heating system stops working and forces the residents to freeze. Worst of all, when a problem with heating is detected during the winter cold. The reasons for the failure of the heat supply are different, and their essence is most often incomprehensible to a simple layman. But if you read our recommendations, it will be easy for you to recognize and fix problems in the heating system in order to protect your home from unpleasant surprises.

Signs of poor heating

When rooms are not heated enough in winter, it is felt immediately. Problems with heating in the apartment make themselves felt by discomfort for the inhabitants, the appearance of dampness on the walls and incomprehensible noises that spread through metal pipelines to the whole house.

Problems with the heating system can be characterized by a number of symptoms:

- the system as a whole is poorly functioning;

- the heat supply on different floors is not the same;

- radiators in one room are hot, in another barely warm;

- the "warm floor" system warms up unevenly;

- noise and seething in the pipes is heard;

- coolant leaks from pipes or radiators.

Causes of malfunctions in heating

Most residents of city apartments believe that they do not need to know the structure of engineering systems. Any central heating problems that appear in them in a high-rise building must be resolved by employees of the management company. And it is right. It is better if only one responsible owner will deal with all the affairs. Indeed, in an apartment building, problems with heating often arise precisely because of unauthorized interventions in the smooth functioning of the heating system.

But individual homeowners are forced to understand the problems with heating in a private house and keep the situation under their control. The owner of the house should at least in general terms know about the causes of problems and be able to fix them.

The following reasons can lead to problems with the heating system:

- the system is not designed correctly;

- equipment does not meet design requirements;

- the system is unbalanced due to unauthorized connections;

- installation was performed poorly;

- air plugs interfere with the circulation of the coolant;

- radiators installed incorrectly;

- pipelines have fallen into disrepair;

- connections are broken.

Let us consider in more detail each of these causes and ways to eliminate problems with heating in an apartment and in a private house.

Errors in the design of the heating system

The development of a heating system project must be given due attention so that in the future the problems of heating a private house do not poison everyday life. Attempts to save money on competent design turn into troubles. For example, when starting a fully assembled system, problems with heating radiators suddenly appear, some of which do not heat up. This means that the system was originally designed incorrectly and will have to be redone.

Design can only be entrusted to specialists who will take into account many factors. Among them: the layout of the house, the volume of heated rooms, the degree of heat loss, etc. It is also important to plan the required slope of the horizontal sections of pipelines. Also, the main technical parameters of the required equipment can be determined only on the basis of thermal engineering calculations.

For reliable heating of the house, the heating boiler must have a capacity of at least 1 kW for every 10 m² of premises with a ceiling height of up to 3 m.

Inappropriate home heating equipment

With the current wide range of heating equipment, it is easy to make a mistake and purchase the wrong one. To avoid problems in the heating system, it is necessary to focus on the compliance of all its elements with the approved project. You need to buy radiators only of the type and with the number of sections as planned. All piping fittings, control and shut-off valves must be mutually compatible.

Problems with heating in a private house often arise due to poor circulation. Circulation pumps help to increase the speed of movement of the coolant in the pipes. But you need to select the right pump model correctly so that noise in the pipes does not appear during its operation.

When arranging modern housing, more practical metal-plastic and polypropylene pipes are increasingly replacing old iron pipes. The absence of problems in each particular heating system will depend on their compliance with the specified project conditions. Although plastic pipes are lightweight and easy to assemble, it is better to entrust the specialist with the correct selection and subsequent installation of these products.

It is important to know that not all types of plastic pipes are suitable for heating systems. Some of them under the influence of hot water, some may be deformed or burst.

Unbalance of the heating system

Serious problems with heating in an apartment building arise when tenants start repairing and redevelopment of their apartments. Spontaneous, uncontrolled installation of new radiators and underfloor heating leads to an imbalance in the system. As a result, the circulation in the system is disturbed, on some floors the radiators are hot, and on others the residents are cold. The specialists of the management company can balance the distribution of the coolant over the risers, but problems with heating in individual apartments still remain.

If the neighbors have changed their heating appliances and removed the thermostats, then it is not surprising that water simply will not go through the pipes to your apartment. And it will be possible to solve such a problem with heating only by removing the thermostat also at home.

Another opportunity to really increase the flow of heat into your apartment is to follow the example of your neighbors and change the batteries. If you install aluminum or bimetallic instead of cast iron, their heat dissipation will be much better.

Unauthorized change of radiators is prohibited, you need to get permission!

The heating system can also be unbalanced in a private house. Then the radiators located closer to the boiler heat up more than the distant ones. You will have to restore the balance in this way: close the control valves and limit the flow of coolant flowing to the near radiators so that more heat flows to the far ones.

Poor installation of the heating system

It happens that a new, recently installed radiator does not want to heat up.

Others standing in the system before and after it heat up normally, but this one does not. The reason is poor circulation of the coolant. The reason for the problem with the heating radiator could be an oversight of the installer. Probably, when welding a polypropylene pipe, he overheated it too much, and as a result of melting, the inner diameter decreased. In such cases, the installer is obliged to redo his poor-quality work free of charge.

In order to avoid problems with the heating system, all pipes and fittings included in its composition must be a securely mounted structure.

Air pockets in heating

If the batteries do not heat in any of the rooms, it means that the air accumulated in the system prevents the free movement of the coolant. An air lock can form due to many reasons, among which we can mention the following:

- air enters when water is drained from the system and then refilled;

- oxygen is released from water when heated;

- a faulty expansion tank creates a local low pressure zone;

- air is sucked into the system through connections with broken tightness;

- air diffuses through the surfaces of the plastic pipes.

Air bubbles may accumulate either at the highest point of the piping system, or in only one of the radiators. Then the bottom of the battery will be hot, and the top will remain cold. The presence of air in the pipes also provokes the appearance of unpleasant gurgling sounds. Most often, heaters on the top floor of the building stop heating up.

The more complex the configuration of the heating system in your home, the slower it should be filled to avoid air locks.

Due to air bubbles, not only does the heat supply through the piping system stop, but the corrosion of metal elements also begins. The smooth operation of the circulation pump is also disturbed.

The use of simple technical devices will help get rid of the problem of clogging the heating system with air traffic jams.

The most effective way to remove air from a closed heating system can be considered the use of automatic air vents. If they are mounted in several problem areas at once, then air from each group of system elements will be bled as it accumulates.

In addition to automatic, there are also manual air vents (Mayevsky crane). Such a device is installed at the end of the radiator, located on the highest of the floors. To learn how to use it, you can watch the video presented here.

How to bleed air through the Mayevsky tap

Depending on how the heating system is arranged, sometimes it is necessary to release it from the air through the expansion tank in the attic. The circulation pump is also able to help expel air congestion from the system.

Incorrectly installed heating radiators

The issue of proper installation of batteries is most relevant for private homeowners, since they themselves have to regulate the heating in their home. Self-replacement of radiators should be treated with responsibility, because their installation without preliminary calculations can add unnecessary problems to the heating system.

For example, the installation was done according to the instructions, and one of the radiators works at half strength. It turns out that it was skewed and the coolant cannot fill it entirely. And the reason is that a heavy multi-section radiator was hung on only two brackets, although it would be more reliable to use four. As a result, the metal structures caved in and the inner tubes deformed.

The reliability of the radiator also depends on its location. The lower edge of the battery should be raised 10 cm above the floor, there should be 2-3 cm of free space between the radiator and the wall.

Each radiator must hang on reliable brackets without sagging, backlash and distortions.

Reducing the clearance in old heating pipes

In the old "Khrushchev" problems in the heating system are obvious and predictable. There, the service life of the pipelines has expired long ago, and therefore they cause not only a decrease in heat, but also accidents. Over many decades, pipes become so clogged with deposits that they are unable to provide normal circulation. The decision should be cardinal - to replace all pipes.

In addition, a decrease in pressure in the system is caused by the formation of scale on the heat exchanger of the heating boiler. Such consequences lead to the use of too hard water. To prevent such a problem with heating devices, special reagents are added to the system to soften the water.

Heating pipe leak

The cause of interruptions in the heating network is often a leak caused by corrosion or poor-quality pipe connections. If the place of leakage is in plain sight, then the problem with heating in the apartment can be solved faster. It is bad if the connection is hidden in the thickness of the wall or in the floor. Then you have to cut off the entire leaking branch of the pipeline and mount a new one.

How to fix a leak if necessary? To do this, it is recommended to keep in stock simple plumbing devices for clamping pipes of the appropriate diameter. In extreme cases, you can make a homemade clamp: wrap a piece of soft rubber around the leak, and then tighten it tightly with wire.

If a leak is found at the junction of the radiator sections, you will have to bandage this area with a strip of cloth, which must first be impregnated with moisture-resistant glue. It is permissible to use a special sealant, "cold welding" and other means.

The proposed methods of dealing with the problem of the heating system leaking are only temporary, and subsequently a major overhaul will be required.

In advance, before the start of the heating season, inspect all pipelines and radiators in the apartment for leaks. Owners of an autonomous heating system should test its performance in the fall.

Finally, we can advise: for all problems with heating in an apartment or in your private house, contact the specialists. Only they know how to properly design the system, install the boiler, piping and connecting radiators.

Do not skimp on the quality of the purchased equipment, so as not to spend money on re-repairs if a cheaply bought tap suddenly breaks and floods the room.

Learn to correctly identify the causes of heating problems and begin to eliminate them competently. In other words: think twice - repair once!

In water heating systems, it is not uncommon for a problem to occur that leads to a deterioration in the circulation of water inside the circuit. The problem has a specific name - airing in the heating system. The uninterrupted operation of water heating is based on the principles of circulation of hot water (coolant) inside the circuit and heat transfer through radiators that heat the premises. The air in the system leads to the appearance of air pockets and, as a result, to the inefficient functioning of the entire system due to a decrease in heat transfer.

To begin to solve the problem, it is necessary to establish the causes of the appearance of air: natural or artificial. The natural cause is the airing of the system due to the property of heated water to release air. The higher the temperature of the coolant, the more air bubbles are released. According to physical laws, the accumulation of bubbles occurs in the upper part of the circuit, since air is lighter than water.

The rest of the reasons are considered artificial. It is difficult to give a complete list, but the main reasons are considered to be the following:

- lack of pressure in the system;

- errors in the installation of the heating circuit (for example, incorrect pipe slope);

- errors when starting the system into operation (for example, filling the circuit with water too quickly);

- high concentration of air in the water used;

- incorrect operation of the locking equipment (possibly loose connections of individual elements);

- blockage of pipelines;

- consequences of repair and maintenance work;

- corrosion on the metal surfaces of the contour elements;

- incorrect operation of air vents or their absence.

Consequences of airing

The disruption of heat transfer due to air locks is unpleasant for residents who pay for heating, but in fact receive an underestimated indoor temperature. But this is not the only negative, there are other negative consequences:

- noise and vibration during water circulation, which in the worst case is fraught with the destruction of integrity at the junction of the circuit elements;

- defrosting the system if there is no water circulation in several radiators;

- excessive fuel consumption in order to increase heat transfer;

- destruction of internal metal parts under the influence of air (due to corrosion).

The totality of all the consequences affects the operating capabilities and the overall service life of both individual elements and the entire heating system.

De-airing

Airing can occur when the system is filled with coolant and during operation. Situations are resolved in different ways, but it all comes down to air release using valves and taps built into the system.

Filling a closed system with forced circulation must occur in a certain sequence to avoid the formation of air pockets. Cold water is supplied from the bottom up, the air outlet valves are left open, only those installed for draining water are closed. Rising, the coolant squeezes out air through open valves and taps. As water begins to run through the tap, it is closed. So gradually, always smoothly, fill the system with water. The pump is started when the circuit is completely filled with coolant.

For air release, manual or automatic air vents, air separators are used. It is clear that the installation of manual air vents involves the release of air by the attendants or the tenant of the apartment (house). There are such air vents in ordinary residential buildings in the rooms of the upper floors or on technical floors. The Mayevsky faucet is known to many residents of old high-rise buildings, who independently discharge accumulated air every heating season. In new houses, it is practiced to install a manual drain valve on technical floors.

The automatic air venting system works separately from human participation. The principle of operation of automatic air vents is the same. In the body of the air vent there is a float on which water enters. The float presses on the spring-loaded rod, opening access to the outside. The body is gradually filled with coolant, the float presses on the rod and closes the outlet. In order for the air vent to work properly, periodically check the cleanliness of the needle and the suitability of the sealing ring for further operation.

The need for separators arises in the operation of large heating systems, where manual reset is problematic. The separator copes with the removal of air dissolved in water. It converts the air into bubbles and removes them from the system. In parallel, the separator (depending on the model) can trap impurities that are present in the coolant (sludge).

All air vents are mounted at critical points - at pipe bends and at the highest points of the circuit.

The heating system must provide uniform heating of all rooms. If the temperature drops in radiators or risers, then circulation is often the cause. For efficient operation of the heating network and comfortable climatic conditions in housing, there must be free circulation of the coolant through the main. This should be taken care of at the design stage. Why there is no circulation of the coolant in the riser and line and what needs to be done, you should know thoroughly in order to quickly eliminate this problem in the future.

The circulation of water in the system is disrupted due to complete or partial blockage in the riser or in the connection to the heating device, airing of the line, freezing of the network, errors in pipe laying. It also leads to misregulation of the central heating system and the appearance of coolant leaks.

Poor pump performance

The purpose of the pump is to maintain the required water pressure in the heating circuit. A well-functioning pump must meet the following requirements:

- Required indicator of work productivity;

- pressure;

- Instrument pressure;

- Compliance with the type of liquid;

- Compliance with the diameter of the pipes;

- Dimensions of the device in accordance with the length of the line.

What to consider when choosing a pump

The pump must be able to handle its load. But it is necessary to take into account whether it will work constantly or will turn on only to feed the heating system and adjust the pressure. This should be taken into account when choosing the power of the pump. For a pump that runs continuously, it is important to consider the power consumption figure.

The pump must be able to handle its load. But it is necessary to take into account whether it will work constantly or will turn on only to feed the heating system and adjust the pressure. This should be taken into account when choosing the power of the pump. For a pump that runs continuously, it is important to consider the power consumption figure.

If you choose the pump incorrectly, then it will not “push” the coolant well, and as a result, the battery warms up unevenly, and the pump itself may burn out from overheating. Poor water circulation will also be noted if the diameter of the components to be connected to the system is incorrectly selected.

When the pump is selected correctly, the heating system functions reliably and fully, and the movement of water is unhindered.

If there are difficulties with choosing a pump, then it is better to contact specialists, they will help you choose the right device for a particular heating system.

Incorrectly selected pipe diameter

This is also one of the common causes of poor water circulation in the heating mains. It is necessary to choose the diameter of the pipes at the design stage.

This is also one of the common causes of poor water circulation in the heating mains. It is necessary to choose the diameter of the pipes at the design stage.

First of all, it must be taken into account that for different heating systems there are rules by which pipes are selected.

If the heating network is supplied to the central heating main, then the diameter of the pipes is chosen similarly to the apartment heating system. For autonomous heating, such diameters may differ. It all depends on whether there is a circulation pump in the system or work will be carried out due to the natural circulation of water.

The choice is also influenced by:

- Pipe production material;

- Type of coolant used;

- Specific features of the wiring of the heating main;

- Planned pressure in the system;

- The speed of movement of water along the highway.

Important! When calculating the diameter, the type of pipes must be taken into account, because the measurement system differs based on the material of manufacture. Steel and cast iron products are marked taking into account the inner diameter, and copper materials according to the outer section. This must be taken into account when planning the pipeline, where several different materials are combined in the line.

Clogged system

As already noted, if there is no water circulation in the riser and heating system, then the problem may be in the debris accumulated in the system. A coarse filter will help get rid of it.

As already noted, if there is no water circulation in the riser and heating system, then the problem may be in the debris accumulated in the system. A coarse filter will help get rid of it.

Dirt that has entered the pipes is easier to remove by catching it in the filter. First of all, the pump is protected by such a filter. It is also recommended to install a filter at the boiler inlet. Such a water filter should be placed in front of each plumbing fixture. When installing the device, pay attention to the filter housing. It has an arrow that indicates which side to install the filter, depending on the direction of movement of the coolant.

The filter should be cleaned regularly. To do this, it is necessary to turn off the water, unscrew the cork, remove the mesh, rinse it, put it in place and screw the cork back, after which you can open the taps.

Advice! To prevent clogging of the pipeline, during installation it is necessary to control that there is no debris in the pipes; for this, the ends are covered in the pipes. It is also necessary to check the radiators, as new products may contain factory shavings or other debris.

Airiness of the heating system

If the installation of the line is performed in violation of the rules, then air jams are formed. They block the flow of water. To quickly solve such a problem, air vents or a Mayevsky crane are installed. For the central system, where a lot of air accumulates, Mayevsky automatic cranes are used. The air is quickly removed and the movement of the coolant through the network is restored.

If the installation of the line is performed in violation of the rules, then air jams are formed. They block the flow of water. To quickly solve such a problem, air vents or a Mayevsky crane are installed. For the central system, where a lot of air accumulates, Mayevsky automatic cranes are used. The air is quickly removed and the movement of the coolant through the network is restored.

These devices not only improve the circulation of the coolant through the central heating line, but also reduce heating costs.

check valves

Often, for normal circulation in the network, some pumps are not enough, then check valves are installed. In this case, each circuit can work independently of the others. Even in a branched radiator system with several circuits, where there are several pumps, it is better to install check valves. Don't skimp on installing them.

Often, for normal circulation in the network, some pumps are not enough, then check valves are installed. In this case, each circuit can work independently of the others. Even in a branched radiator system with several circuits, where there are several pumps, it is better to install check valves. Don't skimp on installing them.

The absence of these mechanisms leads to the fact that the movement of water in the system slows down. This happens in situations where a network with several circuits is laid. In order for warm water to flow along such a circuit where the pump operates, and its movement occurs in the right direction, check valves are used. These elements are not always set, but only in situations where there are no other technical solutions. This is explained by the fact that these elements create high hydraulic resistance, depending on the design. Therefore, the installation of these valves in systems with natural circulation has its limitations, and the reason for the limitations is the low water pressure in the line.

The actuator in the product is a spring that closes the shutter when the normal operating conditions of the heating network change. For systems with different operating parameters, products with appropriate spring elasticity and massiveness are selected. Valves are a very important element, they ensure trouble-free operation of the central heating system, increase the efficiency of all equipment and improve circulation.

Leaks in the system

If the system does not have good water circulation, there may be a leak in some areas. As a result of a leak, the network does not work correctly, the water movement is poor and the boiler starts to malfunction.

If the system does not have good water circulation, there may be a leak in some areas. As a result of a leak, the network does not work correctly, the water movement is poor and the boiler starts to malfunction.

The first thing to do is to find "weak" places. Leaks occur in places where connections have become loose due to corrosive damage, or poor system installation is the cause. If the network is mounted openly, then it is not difficult to check. All such damages are determined quickly and easily. And to inspect a closed highway, you will have to call a specialist.

If a problematic place is found, then it is necessary:

- Tighten loose connections and rewind with sealing tape or tow;

- Replace worn out nodes;

- Cut and replace damaged pipe sections.

The effective operation of the heating system depends on how comfortable the temperature will be in the cold season in the house. Sometimes there are situations when hot water is supplied to the system, and the batteries remain cold. It is important to find the cause and eliminate it. To solve the problem, you need to know the structure of the heating system and the reasons for the cold return during hot supply.

Heating system device - what is a return?

The heating system consists of an expansion tank, batteries, and a heating boiler. All components are interconnected in a circuit. A fluid is poured into the system - a coolant. The fluid used is water or antifreeze. If the installation is done correctly, the liquid is heated in the boiler and begins to rise through the pipes. When heated, the liquid increases in volume, the excess enters the expansion tank.

Since the heating system is completely filled with liquid, the hot coolant displaces the cold one, which returns to the boiler, where it heats up. Gradually, the temperature of the coolant increases to the required temperature, heating the radiators. The circulation of the liquid can be natural, called gravity, and forced - with the help of a pump.

The return is a coolant that, having passed through all the heating devices included in the circuit, gives off its heat and, cooled, enters the boiler again for the next heating.

Batteries can be connected in three ways:

- 1. Bottom connection.

- 2. Diagonal connection.

- 3. Side connection.

In the first method, the coolant is supplied and the return is removed at the bottom of the battery. This method is advisable to use when the pipeline is located under the floor or baseboards. With a diagonal connection, the coolant is supplied from above, the return is discharged from the opposite side from below. This connection is best used for batteries with a large number of sections. The most popular way is side connection. Hot liquid is connected from above, the return flow is carried out from the bottom of the radiator on the same side where the coolant is supplied.

Heating systems differ in the way pipes are laid. They can be laid in one-pipe and two-pipe way. The most popular is the single-pipe wiring diagram. Most often it is installed in multi-storey buildings. It has the following advantages:

- a small number of pipes;

- low cost;

- ease of installation;

- serial connection of radiators does not require the organization of a separate riser for draining liquid.

The disadvantages include the inability to adjust the intensity and heating for a separate radiator, the decrease in the temperature of the coolant as it moves away from the heating boiler. To increase the efficiency of single-pipe wiring, circular pumps are installed.

For the organization of individual heating, a two-pipe piping scheme is used. Hot feed is carried out through one pipe. On the second, the cooled water or antifreeze is returned to the boiler. This scheme makes it possible to connect radiators in parallel, ensuring uniform heating of all devices. In addition, the two-pipe circuit allows you to adjust the heating temperature of each heater separately. The disadvantage is the complexity of installation and the high consumption of materials.

Why is the riser hot and the batteries cold?

Sometimes, with hot supply, the return of the heating battery remains cold. There are several main reasons for this:

- incorrect installation;

- the system or one of the risers of a separate radiator is aired;

- insufficient fluid flow;

- the cross section of the pipe through which the coolant is supplied has decreased;

- the heating circuit is dirty.

Cold return is a serious problem that must be fixed. It entails many unpleasant consequences: the temperature in the room does not reach the desired level, the efficiency of radiators decreases, there is no way to correct the situation with additional devices. As a result, the heating system does not work as it should.

The main trouble with cold return is the large temperature difference that occurs between the supply and return temperatures. In this case, condensate appears on the walls of the boiler, reacting with carbon dioxide, which is released during the combustion of fuel. As a result, acid is formed that corrodes the walls of the boiler and reduces its service life.

How to make radiators hot - looking for solutions

If it is found that the return is too cold, a series of troubleshooting steps should be taken. First of all, you need to check the correct connection. If the connection is not made correctly, the downpipe will be hot, but should be slightly warm. Pipes should be connected according to the diagram.

In order to avoid air locks that impede the movement of the coolant, it is necessary to provide for the installation of a Mayevsky crane or a bleeder for air removal. Before venting, shut off the supply, open the valve and let the air out. Then the tap is closed, and the heating valves open.

Often the cause of the cold return is the control valve: the cross section is narrowed. In this case, the crane must be dismantled and the cross section increased using a special tool. But it is better to buy a new faucet and replace it.

The reason may be clogged pipes. It is necessary to check them for patency, remove dirt, deposits, clean well. If patency cannot be restored, clogged areas should be replaced with new ones.

If the coolant speed is insufficient, it is necessary to check whether there is a circulation pump and whether it meets the power requirements. If it is missing, it is advisable to install it, and if there is a lack of power, replace or upgrade it.

Knowing the reasons why heating may not work effectively, you can independently identify and eliminate malfunctions. The comfort in the house during the cold season depends on the quality of heating. If you do the installation and testing of the heating system yourself, you can save on hiring third-party labor.

Sometimes the heating system works intermittently, which causes the house to cool down and its residents to freeze. If in the warm season there is time for repairs, then in winter it is necessary to identify the breakdown as soon as possible. Usually the reasons that there is no circulation in the heating system are unknown to the layman. But after getting acquainted with some of the characteristics of the equipment and recommendations for its repair, the owner of the house will be able to fix the problem on his own.

Show all

Signs of breakdowns

If the room does not warm up enough in winter, then it is felt immediately. The lack of heating is manifested not only by the discomfort of the residents. The walls are covered with mold and fungus, the rooms smell of dampness, and strange noises are heard in the pipelines.

If the room does not warm up enough in winter, then it is felt immediately. The lack of heating is manifested not only by the discomfort of the residents. The walls are covered with mold and fungus, the rooms smell of dampness, and strange noises are heard in the pipelines.Problems may be accompanied by some symptoms:

- poor functioning of the system;

- heat is supplied unevenly throughout the room;

- cold batteries in the rooms;

- if underfloor heating is installed, they heat up in places;

- gurgling and metallic clanging is constantly heard from the pipes;

- coolant flows out of the radiators.

If several of these signs occur, then it is necessary to identify the cause of the breakdown and eliminate it. Otherwise, the system will function even worse.

Causes of problems

Most residents of private houses and apartments do not consider it necessary to understand the engineering design of the heating system. The solution of all problems that arise with the central structure, they assign to the employees of the relevant services. Although it is really better to entrust repairs to qualified specialists, you need to learn how to deal with minor breakdowns on your own, because sometimes they can be fixed at home.

Such knowledge is indispensable for the owners of private houses and cottages, where the entire system is under the control of one person. The owner must know at least the general design of the equipment and be able to identify minor problems.

The main reasons why there is no circulation in the heating system:

- incorrect design;

- non-compliance of equipment with design requirements;

- imbalance due to unauthorized connections;

- poor-quality installation;

- the formation of air congestion;

- improper installation of radiators;

- pipeline damage;

- violation of tightness in seams and joints.

Each cause must be considered separately, because it is accompanied by different consequences.

Mistaken Design

Before installing the system, the master or the owner of the house himself draws up an engineering project. All calculations and measurements must be carried out very carefully, since the slightest mistake can lead to equipment malfunctions. This takes into account the layout of the house, its area, the number of radiators, the climatic conditions of the region, the presence or absence of other heating systems and heaters.

Before installing the system, the master or the owner of the house himself draws up an engineering project. All calculations and measurements must be carried out very carefully, since the slightest mistake can lead to equipment malfunctions. This takes into account the layout of the house, its area, the number of radiators, the climatic conditions of the region, the presence or absence of other heating systems and heaters.You can't skimp on a quality project. Otherwise, when starting the equipment, several batteries may be left unconnected or water will flow out of the pipelines. Then you have to turn off the entire system and design it again, again making calculations and creating drawings and diagrams.

Specialists who should be entrusted with this painstaking and hard work take into account all the factors affecting the normal functioning and reliability of heating units. Be sure to plan the slope of the vertical and horizontal sections of the pipeline. The technical parameters of the equipment itself can be found in the documents attached to it. The optimal boiler performance should be at least 1 kW for every 10 square meters of room area with 3 m high ceilings.

Heating system with natural circulation without pump and electricity

Poor quality equipment

Due to the wide range of heating boilers and the variety of models, manufacturers, the buyer can easily make a mistake in choosing the right unit. Therefore, it is necessary to focus on the approved project. All parts and elements of equipment must comply with its requirements.

Due to the wide range of heating boilers and the variety of models, manufacturers, the buyer can easily make a mistake in choosing the right unit. Therefore, it is necessary to focus on the approved project. All parts and elements of equipment must comply with its requirements.It is according to the plan that they acquire a certain type of radiators with a suitable number of sections in them. Shut-off valves, adjusting elements and connecting assemblies must be mutually compatible.

Most often, problems occur due to insufficient circulation of the coolant through the pipes. Special pumps can enhance the movement of water, but they must be chosen carefully, otherwise the devices will become a source of hum and noise. Additionally, they replace old iron pipes with modern products made of metal-plastic or polypropylene. This will avoid some problems in certain heating systems.

Plastic pipelines are easy to install and connect to the boiler, but it is better to entrust this work to the master. After all, not all types of plastic are suitable for use in heating equipment, some models do not withstand high temperatures and burst under their influence.

Unbalance and installation

Another reason why water does not circulate in the heating system is an incorrect imbalance during the repair or redevelopment of the apartment. This is affected by the uncontrolled installation of new radiators and underfloor heating.

Batteries on some floors continue to function normally, on others they will remain cold, since they do not receive coolant. Although the masters will easily balance the distribution of water across all risers, the system will not work in several apartments.

If some tenants removed the thermostats when replacing heating equipment, then heat will not flow into their neighbors' dwelling. To eliminate this problem, it is necessary to eliminate the thermostats in all apartments. You can increase the heat supply if you follow the example and also replace all the radiators. Bimetallic or aluminum batteries will harmoniously fit into modern heating systems. You must first obtain permission to replace devices, since you cannot do this yourself.

In a private house, batteries located closer to the boiler heat up more than others. To restore balance, you need to close the adjustment valves and limit the access of the coolant to nearby radiators. But sometimes a new battery does not heat up. If the whole system worked fine before its installation, then the problem lies in improper installation. When welding several polypropylene pipes, the master overheated the product, due to which its inner diameter decreased. The specialist must redo all the work for free. All structural elements must be securely and efficiently fastened.

Gravity heating system in the house

Air locks

Cold batteries are usually caused by air preventing water from flowing freely.

Air lock is formed for several reasons.:

Oxygen bubbles accumulate in one of the batteries or at the top of the heating system. Because of this, the lower part of the radiators will be hot, and the second half cold. And also during the operation of the equipment there are gurgling sounds. In multi-storey buildings in the uppermost apartments, the boilers completely stop working.

To eliminate this problem, automatic air vents are used. It is necessary to install them at once in several problematic places, where the air will be periodically bled. You can mount an expansion tank in the attic through which excess oxygen will escape, or purchase a circulation pump.

Air lock is a problem for the heating system

Problem with radiators and leaking pipes

Preliminary calculations will help private homeowners install new batteries without errors. Incorrect placement of the element will lead to its inefficient operation. Therefore, it is better to use reliable fasteners: four brackets will allow you to hang the radiator better than two parts. The lower edge must be raised on the floor surface by 10 cm, and between the battery itself and the wall there should be a space of 2-3 centimeters.

In old apartment buildings, many pipes have long since expired. Therefore they can cause accidents and reduce the level of heat. Microelements contained in the coolant are deposited inside the pipelines. They impede the normal circulation of water. The correct solution would be to replace the products, but this is not always possible.

Scale layers form on the inner surface of the boiler, which reduces the pressure in the system. This problem leads to the use of hard water, saturated with minerals and salts. Special reagents must be added to the equipment, which soften the qualities of the coolant.

Corroded or improperly connected pipes cause leakage. If it is located in a prominent area, then it is easy to seal the hole with sealants. It is more difficult to deal with a problem hidden in a wall or floor. In this case, you will have to cut off the entire branch, fix the problem and mount a new section. In addition to sealants, you can use special parts to clamp the pipeline, corresponding to its diameter. If it is not possible to purchase such devices, then it is enough to make a clamp. The place of leakage is covered with a piece of soft rubber and tightly fixed with wire.

If a leak is detected on the radiator or its junction with the pipe, the hole is wrapped with a strip of fabric, after soaking it in construction moisture-resistant glue. Sometimes cold welding is used. To avoid such problems, before the start of the heating season, the entire system is inspected for damage. Be sure to start the boiler and check the quality and reliability of its work.

Often there is no circulation in the heating system. What to do in this case - the owner of the house decides. It is advisable to call a specialist who will quickly and efficiently carry out all repairs. You need to take preventive measures on your own to keep the equipment in working mode.